Spray drying is rapidly drying a liquid or slurry into a dry powder with a hot gas. A laboratory spray dryer is recommended for many thermally sensitive products, such as those used in the food and pharmaceutical sectors. When compared to other ways, spray dryers may dry quite rapidly.

Overview of lab spray dryer:

A lab spray dryer is an equipment that is often used in the laboratory. Its purpose is to dry various items, including soap powder, gasoline, intermediates, and inorganic salts.

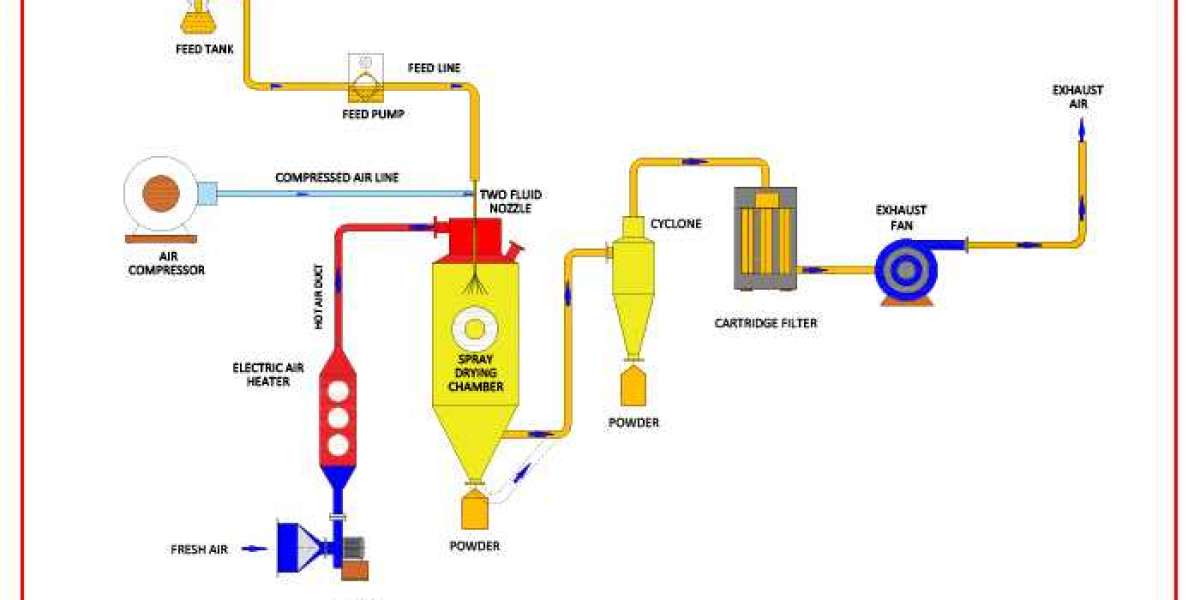

A peristaltic pump pumps the liquid containing solid components through the two-fluid nozzle, and compressed air sprays the solution into tiny droplets into the drying chamber. The fine mist droplets in the heated air have a large specific surface area. They may efficiently conduct heat exchange, causing the surface water vapour to quickly sublime and become dry solid particles. The cyclone separator separates the solid particles from the exhaust gas, entering the collecting container.

Lab spray dryers in the food industry

The lab spray dryer offers a wide range of uses in the food business. Lab Spray dryers manufacturers provide various spray dryers that come with a wide range of benefits in food additives, dairy, and egg industries.

Application of lab spray dryers in processing fruit and vegetable powder:

A lab spray dryer is used to turn fruits and vegetables into powder. Fruit and vegetable powder may overcome the weaknesses of fruits and vegetables, and it satisfies people's need for the variety and freshness of fruits and vegetables.

The dilution ratio of the material liquid, the homogenous pressure of the material liquid, the spray drying feed rate, the input and outlet temperatures, the liquid flow rate, the kind and amount of the drying aid, and other elements all have an impact on the fruit and vegetable powder produced in the lab spray dryer. Colour, flavour, yield, and nutrients all have varying degrees of effect. As a result, selecting a high-performing lab spray drying device is critical.

Lab spray dryer in instant tea beverages:

Instant tea beverage is a solid tea beverage that dissolves fast in the water. It's easy to transport and dissolve in water, leaving no residue, fewer pesticide residues, and the dosage may be adjusted easily. The manufacturing of Ganoderma lucidum black tea solid beverage and the processing technology of instant red date and black Tartary buckwheat milk tea have all benefited from the usage of a lab spray dryer.

Application of lab spray dryer in food additives:

Food additives are sometimes referred to as the "soul" of the contemporary food business. However, since certain food additives are quickly impacted by environmental elements such as light, oxygen, temperature, and moisture, some food additives have unpleasant aromas, their usage in food is severely limited.

These issues were readily remedied with the invention of microencapsulation technology in the twentieth century. Spray drying is the key to microencapsulation technology, and Maltodextrin concentration and shallot oil taste are two examples of research applications in this field.

Application of lab spray dryer in soybean peptides:

Soy peptides are small-molecule proteins that are easily absorbed by the human body, making them ideal for poor protein digestion and absorption. Soy peptides also improve immunity, physical strength, tiredness relief, and the reduction of three highs. They're significant elements for a healthy diet. The lab spray dryer may adjust the entrance and output air temperature. The active components of soybean peptides are unaffected by using a lower inlet air temperature. As a result, a lab spray dryer can swiftly generate soybean peptide powder, which is milky white and has high solubility.

Industrial spray dryers manufacturers in Mumbai

Industrial spray dryers manufacturers in Mumbai have advanced over time. Spray dryers may now be used to treat everything from milk powder to pharmaceuticals. Experimental and RD versions of industrial spray dryers are available. Spray dryers can be used for various purposes, including drying, fine powdering, powder mixing, agglomerating, encapsulating, and englobing. Paint pigments, ceramic materials, catalytic supports, and microalgae are all made by spray drying in the food and pharmaceutical sectors.

Applications of industrial Spray Dryer:

Spray drying is used in pharmaceutical production for amorphous solid dispensation, which involves evenly distributing active medicinal components into a polymer matrix. It raises the energy level of the dynamic features in the medicine, making it easier for the drug ingredients to diffuse throughout the patient's body. Spray drying also produces antibiotics, pharmaceutical compounds, and additives.

Several beverage elements are spray-dried to prepare instant drink mixes. The method can also remove moisture from foods, such as powdered milk, especially skim. Lower operating temperatures and bigger chamber sizes for longer residence durations help prevent thermal damage of items. Powdered eggs, coffee, tea, spices, flavourings, starch and starch derivatives, enzymes, vitamins, sugar replacements like stevia, nutraceuticals, colourings, animal feed, and other items are all made using this method.

This article demonstrates the applications of spray dryers in the industry. Spray dryer manufacturers in India can guide you for additional information on related items.