Clarifiers for Wastewater Treatment are ultra-expensive to maintain, but using them inaptly can cost you further than just a fine levied by authoritarian agencies.

This is why it's a must that wastewater co-ordinators know the difference between the primary and secondary clarifiers for wastewater treatment. It might be easy to get them mixed up, but there's one clear physical property distinguishing between the two.

Not following the proper norms and procedures can affect an entire community burdened by polluted drinking water, which can transmit conditions similar as cholera, diarrhoea, typhoid, polio, and more.

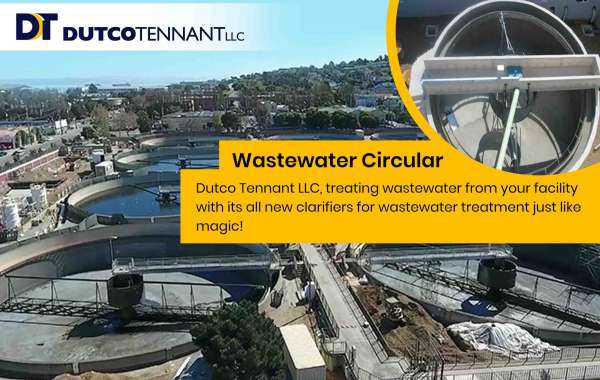

From Dutco Tennant LLC, you can get a complete range of settlement sewage tank clarifiers for wastewater treatment in rotating and traveling types.

Each Clarifier for wastewater treatment carries a distinct purpose concerning consistency. The primary clarifier is designed to dispose of inorganic solids floating at the surface. It also tackles solids settling at the bottom. In this unit, the sludge is less thick. While, in the secondary clarifier, 100 percent or nearly 100 percent of the sludge, is organic. In this clarifier for wastewater treatment by Dutco Tennant LLC, the sludge is compact-ready and significantly thick.

Also known as sedimentation, the primary clarification process can be described as the disposal of inorganic solids before biological treatment. The step-by-step process is as follows

- At first, water enters the clarifier tank.

- Skimmers remove the inorganic solids (scum) floating on the top.

- Rake collects the sludge settling at the bottom and further removed by the sludge discarding system.

- The biologically treated effluent leaves the clarifier over a weir.

A good primary clarifier for wastewater treatment by Dutco Tennant LLC is anticipated to remove 90 to 95 percent sludge, 40 to 60 percent scum, and around 25 to 50 percent Biological Oxygen Demand ( BOD).

Any primary clarification process that involves Dutco Tennant LLC supplied clarifiers for wastewater treatment, intends to remove as significant waste as possible, but some factors can avoid the stylish results.

- Sludge build-ups: This decreases tank volume.

- Largely concentrated waste channels: This includes a high solid count and high BOD degrees. In this case, the clarifier will have trouble reusing its sludge volume and will not operate duly.

- Hydraulic surcharge and hydraulic under load: Overload decreases hydraulic detention time and under load prevents the equipment from working at full capacity, wasting its use and energy.

Proper administration of Dutco Tennant LLC provided primary clarifiers for the wastewater treatment process will assure smooth transitioning to the secondary clarifier process.

Dutco Tennant LLC supplied secondary clarifiers for wastewater treatment can be described as a circular container where effluent from the activated sludge process is retained. The process is as follows

- Activated Sludge: The biomass of microorganisms settles to the bottom in the form of activated sludge.

- Aeration tank: After settling over some time, this biomass of microorganisms is returned to the first aeration tank.

- Repeat: This cycle replays until only clean water is left.

- Dispatch: The clean water that remains flows to the top of the clarifier and is further dispatched for disinfection.

Understanding the difference between the primary and secondary clarifiers for wastewater treatment is only one piece of the enigma. There is a lot to know about Dutco Tennant LLC presented clarifiers for wastewater treatment. Dutco Tennant LLC supplied and widely accepted clarifiers for wastewater treatment supplies:

- Wastewater Circular/Rectangular Clarifiers

- Wastewater Lamella Clarifiers.

You can rely on Dutco Tennant LLC as a wide range of Supplies are already being provided all throughout the Middle-Eastern regions.